Qingdao Steel Orders Flat Bar Rolling Mill from Siemens

10/23/2013 - Siemens Metals Technologies has won an order to supply Chinese steel manufacturer Qingdao Special Iron & Steel Co. Ltd. with a flat bar rolling mill.

The new mill will have a production capacity of 600,000 metric tons a year. It will manufacture flat bars with widths of between 60 mm and 160 mm and thicknesses from 6 mm to 60 mm for applications in the automotive and construction industries. Commissioning is scheduled for the start of 2015.

The new mill will have a production capacity of 600,000 metric tons a year. It will manufacture flat bars with widths of between 60 mm and 160 mm and thicknesses from 6 mm to 60 mm for applications in the automotive and construction industries. Commissioning is scheduled for the start of 2015.Qingdao Steel is located in Qingdao in the eastern Chinese province of Shandong, and it has an annual production capacity of 1.2 million metric tons of crude steel. It produces structural steels, pipes and steel nails, primarily for the Chinese market. The new flat bar rolling mill is part of Qingdao Steel's program of relocating and modernizing plants to comply with local authority environmental requirements. Siemens' supply also includes new shearing and sawing systems for another of the company's bar lines.

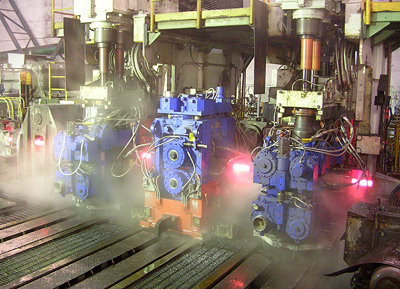

For the flat bar rolling mill, Siemens will supply a four-stand pre-stressed finishing and sizing train in H-H-V-H arrangement, a multi-section thermo-processing equipment that is controlled with the help of the Promet metallurgical simulations tool, a cropping shear before the sizing train, a hot dividing shear, as well as a shear and two abrasive saws for cutting the finished rolled products to length. Spring steel, and carbon and alloyed steels are processed. Siemens will also supply the dedicated mechatronics packages for the automation of the thermo-processing equipment, of the finishing and sizing train, and of the sawing systems.

Siemens is also responsible for designing and engineering the supplied equipment, and will support Qingdao Steel in the erection and commissioning of the rolling mill.

.jpg?lang=en-US&ext=.jpg)

.gif?width=220&height=200&mediaprotectionhash=374c6b9a31f2b2fbfc7937391034efb46fd57feba997b9ad2ae9a0bd3d48329d&ext=.gif)

.gif?width=100&height=200&mediaprotectionhash=e2d5b15d68f84f22038524be6c58e5268d67b7f44494b544e29a8d53c5b959ba&ext=.gif)