| | The use of computer simulation in industrial environments in general and steel is not new and has been widely used for many purposes over the years. Computer simulation has provided value to the steel industry in areas such as steel plant layout and design, process and productivity improvements, and detailed modeling of chemistry and material structures. Simulation has also resurfaced in digital transformation as it can be a component of a digital twin. DEFINITIONA simulation is a computer-based mathematical model that is developed to show the possible behavior of or the effect on a real-world or physical system. A simulation is developed because one cannot “experiment” with the real system (you do not want to change the actual hot rolling sequence because it could cause an operational problem) or there are a variety of factors or attributes to consider and it would be too expensive to try all of them (there are many ways to change the operation of a piece of equipment and you cannot physically try all of them). In general, simulation works very well when it is expensive, dangerous or not physically possible to use the real-world item or items to determine better operating conditions.

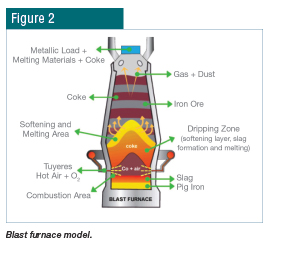

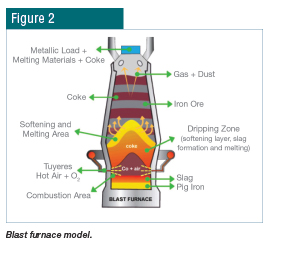

Fig. 1 is a screenshot from a computer simulation of a blast furnace.

Simulation can also be a descriptive tool, in that given a set of conditions, it shows the effect of those conditions on the system. A simulation generally does not optimize a system. Although it is a mathematical model, the mathematics is in the description of the model, not in an optimization algorithm. In many cases, a simulation helps to understand how a system reacts to certain changes and, therefore, provides visibility and understanding, particularly where it may be early in developing an optimization or where it may be mathematically difficult or impossible to develop an optimization model.

Another characteristic of a simulation is that it can be deterministic or stochastic. This refers to whether the simulation model incorporates the ability to generate slightly different values for parameters to determine the sensitivity of those parameters. For example, given that it is a model, the parameters, values or other specifics of the model may not be known exactly and so the model may be run numerous times with slightly different conditions to determine the effect. One common type of stochastic simulation is a Monte Carlo, where many simulation runs are made with random or changing values to see the effect on the results. HISTORYAs mentioned previously, simulation has been used for many years now, with its early origins in the 1950s or before when computers first started to appear. As computers became more widespread, easier to use and more common, the use of simulation for looking at manufacturing processes became more useful. In the 1970s, companies used the FORTRAN language primarily for scientific and technical computing, but it did not have the appropriate structures to be used for simulations without writing considerable code. Several general-purpose simulation languages were developed in the 1970s and 1980s and, with the rapid increase in the speed of computers, simulation became a very popular tool, primarily with industrial engineers and mathematicians.

At that time, simulation began to be used for the design or upgrade of expensive facilities. For example, in the 1990s, some companies instituted a policy of simulating any large capital changes in excess of US$1 million for any of their plants before approving and actually making those changes. Some steel companies used simulation for changing metallurgy or practices to see the effect on energy, utilization or productivity. Many companies continue to use simulation for these and other analyses today.

The continued improvement of computing power in processing speed, cost and accessibility has contributed to the increase in the use of simulation and other mathematical modeling tools. In the early days, it was not unusual for a computer simulation model to take hours or even a day to run to completion. So, one had to devise, check and validate a model carefully as it could take many days or months to make several model runs. Today, those same models could be set up and run in a matter of minutes or less with even a laptop. There is, however, still a small, specialized subset of computer simulations that require large, expensive computers and very specialized staff to operate them. Although not in an industrial setting, simulations of the weather, hurricanes and other large storms are examples of this.

Another major change to simulations and computing over time has been the improvement of the interface. Years ago, one had to type everything into a computer in a specialized language and go through the output very carefully. Today, through easy-to-use graphical user interface, simulations can be built using drag-and-drop techniques and one can use animation to both check the model and examine the results. Much of this advancement in technology derives from the gaming industry, where many of the games are (somewhat) realistic or stylized versions of real-life situations. In many cases today, simulation may be an underlying technology but one that is mostly hidden due to the advances in technology.

Perhaps one thing that has not changed is the work required to validate the simulation model — to determine if it is a good model of the real system so that the result of a model run can be considered close to the situation that would occur with the real system. These modeling steps, while made easier with better technology, still generally require someone with knowledge of the process being modeled and, in some cases, require a mathematician or data scientist to be available to help with the modeling and analyze the results. TECHNOLOGIESAs described earlier, a computer simulation model requires several components, some of which are technology-based. The first is a computer language that can be used to develop a model of the physical system. In its simplest form, a spreadsheet can be considered a financial simulation tool as amounts can be changed and the effect on profit and loss can be shown. For industrial simulations, there are a variety of commercially available simulation languages; however, in some cases, a custom modeling language may need to be developed (as is the case in many university research projects).

A simulation also requires a computer on which to run. With the technology today, this can range from a regular desktop or laptop PC to a large, specialized (and expensive) computer used for this type of computationally intensive modeling. For many projects today, a PC with additional memory and processing power may be enough.

Finally, depending on the type of simulation, it may also require a statistical analysis package to be able to analyze the data and some type of reporting or business intelligence tool to display the results. EXAMPLE APPLICATIONSSome of the applications of simulation in the steel industry have been mentioned earlier. There are perhaps three main categories for the purposes of this article — simulation of operational issues, simulation of material and metallurgy, and simulation of design or equipment.

Simulation of operational issues includes scheduling the facilities, looking at planned inventory levels and identifying bottlenecks in the plant. There is a long history of these types of simulations and many companies use them to both solve operating problems as well as for planning purposes.

The second type is for material and metallurgy, where a detailed model of a melting furnace, for example, may be developed and the simulation shows what happens over time. Other examples are the effect of a cooling procedure or a reheat furnace practice on the steel’s microstructure or metallurgical properties. These can be quite detailed and very complex models.

As a specific example, Fig. 2 shows another view of a blast furnace and the model that was developed to simulate the process as the raw materials are introduced into the furnace. This particular model, based on computational fluid dynamics (CFD), shows the materials such as pig iron, coke and iron ore move over time, come together, and how other factors, such as injecting oxygen into the furnace, affect the formation of the molten steel. A model such as this could change the rate at which the materials come together, the temperature or the amount of oxygen to see the effect on the molten steel. Many model scenarios can be run and better (and worse) options can be determined. As a specific example, Fig. 2 shows another view of a blast furnace and the model that was developed to simulate the process as the raw materials are introduced into the furnace. This particular model, based on computational fluid dynamics (CFD), shows the materials such as pig iron, coke and iron ore move over time, come together, and how other factors, such as injecting oxygen into the furnace, affect the formation of the molten steel. A model such as this could change the rate at which the materials come together, the temperature or the amount of oxygen to see the effect on the molten steel. Many model scenarios can be run and better (and worse) options can be determined.

The third type is used for design or the redesign of a steel mill or part of the plant. For example, a new type of steel process or plant may be simulated before it is built, to show how it might operate. Another example is that a rebuild or redesign of a part of an existing plant may be simulated. The idea is to simulate these kinds of changes before they are done in order to save time, money and effort. SUMMARYComputer simulation has been used as a tool by industry in general and steel in particular for many years, with early models being developed in the 1960s and 1970s. Simulation has matured and is more widespread today because of the dramatic improvements in computing power over the years — computers keep getting faster, cheaper and easier to use. There are still difficult parts to these projects but easier modeling tools, better user interfaces and animation have made it easier to develop simulation models. There is also somewhat of a resurgence of simulation because of digital transformation and the emergence of digital twins, of which simulation can be a part of the model that is developed.

REFERENCES 1. A.M. Law, Simulation Modeling and Analysis, 5th Edition, McGraw-Hill Series in Industrial Engineering and Management, 2014.

2. M.M. Gunal, “Simulation for Industry 4.0: Past, Present, and Future, Springer Series in Advanced Manufacturing,” 2019, doi: 10.1007/978-3-030-04137-3.

3. Wikipedia, Simulation, 2020.

|

As a specific example, Fig. 2 shows another view of a blast furnace and the model that was developed to simulate the process as the raw materials are introduced into the furnace. This particular model, based on computational fluid dynamics (CFD), shows the materials such as pig iron, coke and iron ore move over time, come together, and how other factors, such as injecting oxygen into the furnace, affect the formation of the molten steel. A model such as this could change the rate at which the materials come together, the temperature or the amount of oxygen to see the effect on the molten steel. Many model scenarios can be run and better (and worse) options can be determined.

As a specific example, Fig. 2 shows another view of a blast furnace and the model that was developed to simulate the process as the raw materials are introduced into the furnace. This particular model, based on computational fluid dynamics (CFD), shows the materials such as pig iron, coke and iron ore move over time, come together, and how other factors, such as injecting oxygen into the furnace, affect the formation of the molten steel. A model such as this could change the rate at which the materials come together, the temperature or the amount of oxygen to see the effect on the molten steel. Many model scenarios can be run and better (and worse) options can be determined.